Aassembly for cutting to lenght and tube manufacture

Robust and proven MABI technology.

MABI 16-1 Vario

Cutting line for straightening and cutting of flat sheets

MABI 16-1 Vario

Simple cut-to-length / cross-cutting plant for straightening / cutting straight sheets

- Compact design

- Sheet width 914 mm - 1250 mm

- Up to 5 cuts per minute

- Coil engine in combination with de-coiller MABI 6C

- Working directly from coil (small & large)

- Cutting of stainless steel (V2A):

From 0.5 mm till max. 0.8 mm thickness - Cutting aluminum, zinc sheet:

Min. 0.5 mm up to 1.0 mm thickness

/en/products/assembly-for-cutting-to-lenght-and-tube-manufacture/mabi-16-1-vario/

MABI 16-2 Vario

Cutting line for straightening, cutting, punching and cross swaging of straight sheets

MABI 16-2 Vario

Cutting line for straightening, cutting, punching and cross swaging of straight sheets

- Compact design

- Different programs at a key stroke, no retooling time

- Sheet width 914 mm - 1250 mm

- Up to 5 cuts per minute, both sides holes & cross beads

- Punching (hole distance & number of holes variable programmable)

- Conic punching (straight sheets)

- Coil engine in combination with de-coiller MABI 6C

- Working directly from coil (small & large)

- Cross bead at front or back, also at both sides or without

- Overlap variable 20 / 30 / 50 mm, other overlap

possible on request - Cutting of stainless steel (V2A):

From 0.5 mm till max. 0.8 mm thickness - Cutting aluminum, zinc sheet:

Min. 0.5 mm up to 1.0 mm thickness

/en/products/assembly-for-cutting-to-lenght-and-tube-manufacture/mabi-16-2-vario/

MABI 16-3Z Classic

New: The compact pipe production line for pipe sections ready for assembly

MABI 16-3Z Classic

New: The compact pipe production line for pipe sections ready for assembly

- Compact design

- Different programs at a key stroke, no retooling time

- Cuts: Sheet width 990 - 1010mm

- Up to 5 straight sheets / cuts per minute

- Tubes: Sheet width 1000mm

- Tubes (up to 4 tubes per minute) ready for fitting,

min. d = 80mm - Conic punching (straight sheets and tubes) for offset

swages (50mm from the edge) - Coil engine in combination with de-coiler MABI 6C

- Working directly from the sheet coil (small coil and large coil)

- Cross bead at front or back, also at both sides or without

- Overlap variable 20 / 30 / 50 mm, other overlap

possible on request - Cutting of Inox (V2A) from 0.5 mm till max. 0.8 mm

- Cutting aluminum, zinc sheet

min. 0.5mm up to 1.0mm thickness - Programmable number of holes

- Longitudinal swage one- or bothsides

Options: - Bandwidth 1250 mm

/en/products/assembly-for-cutting-to-lenght-and-tube-manufacture/mabi-16-3z-classic/

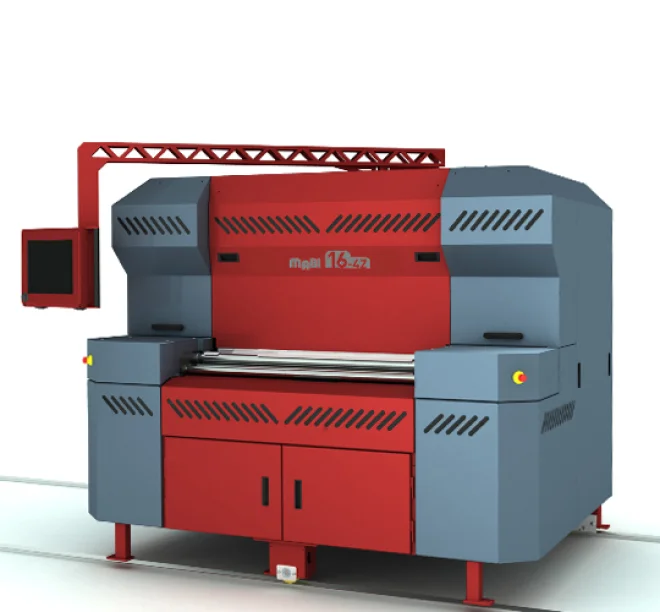

MABI 16-4Z EVO

The fastest and most flexible compact pipe production line from MABI

MABI 16-4Z EVO

The fastest, most versatile and compact pipe production line from MABI.

The new EVO machines, also the new MABI 16-4Z EVO can work with sheet width 914mm and 1250mm without paying extra. Straightening, cutting, punching, beading, rolling and swaging for sheet metal and ready-to-fit ducts.

- Pipe-cladding fabrication-unit

- Punching unit (fast lifting) for standard tubes

- Tubes (up to 8 tubes per minute) ready for fitting

- Straight sheets (min. length 270mm

min. finished tubes

min. diameter 80mm) - Cutting of stainless steel (V2A) from 0.5mm till max. 0.8mm thickness

- Cutting aluminum, zinc sheet min. 0.5mm up to 1.0mm thickness

- Rounding unit 914mm to 1250mm

- Fully automatic bead adjustment

- Automatically printing system

- Prepared for: IsoPlaner with DirectCut (in connection with Laser 2, 4E EVO, Bingo 16-Z EVO, Bingo 2 EVO)

- Working directly from the sheet coil (small coil and large coil)

- Coil engine in combination with de-coiler MABI 6C

- Conic punching (straight sheets and tubes) for offset swages (50mm from the edge)

- Job application on the screen of the machine

- Router for ADSL / DSL (access on the part of the customer)

/en/products/assembly-for-cutting-to-lenght-and-tube-manufacture/mabi-16-4z-evo/

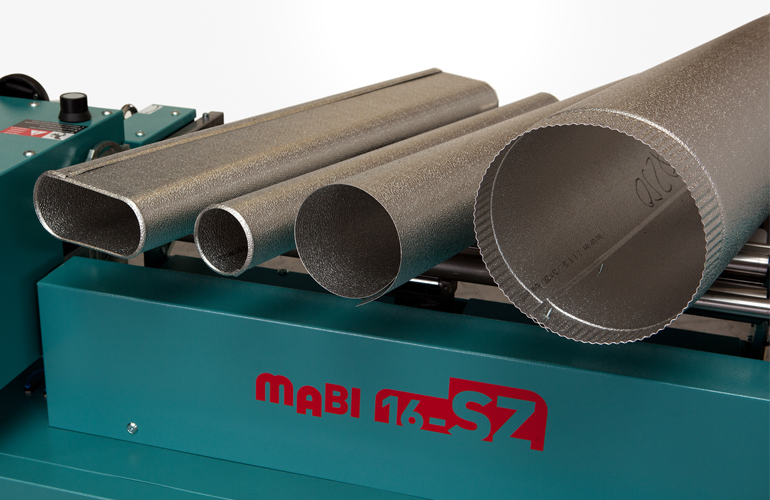

MABI 16-SZ 70 Rohrjet

Rolling and beading machine for the production of pipes. Minimum diameter: 70 mm

MABI 16-SZ 70 Rohrjet

The original that works! Rounding and beading machine for rounding tubes while simultaneously creating the positive and negative beads.

- Minimum diameter: 70 mm

- Maximum diameter: 120 mm

- Can also can be used for bundled pipes

- Can also be used as a normal rounding machine, without beads

- The beading rollers can be replaced within a very short time, unlike with other makes

- Beading and rounding in 3-5 seconds, by means of simultaneous beading and rounding

- Infinitely adjustable speed

- Bandwidth adjustable from 995 - 1010 mm

- 50 mm offset swage

- Inox (V2A) from 0.5 mm till max. 0.8 mm

- Aluminum, zinc sheet min. 0.5mm up to 1.0mm thickness

Options:

- Bandwidth 1250 mm

/en/products/assembly-for-cutting-to-lenght-and-tube-manufacture/mabi-16-sz-70/

MABI 16-SZ 80 Rohrjet

Rolling and beading machine for the production of pipes. Minimum diameter: 80 mm

MABI 16-SZ 80 Rohrjet

The original that works! Rounding and beading machine for rounding tubes while simultaneously creating the positive and negative beads.

- Minimum diameter: 80 mm

- Can also can be used for bundled pipes

- Can also be used as a normal rounding machine, without beads

- The beading rollers can be replaced within a very short time, unlike with other makes

- Beading and rounding in 3-5 seconds, by means of simultaneous beading and rounding

- Infinitely adjustable speed

- Bandwidth adjustable from 995 - 1010 mm

- 50 mm offset swage

- Inox (V2A) from 0.5 mm till max. 0.8 mm

- Aluminum, zinc sheet min. 0.5mm up to 1.0mm thickness

Options:

- Bandwidth 1250 mm

/en/products/assembly-for-cutting-to-lenght-and-tube-manufacture/mabi-16-sz-80/