MABI INSULATION MACHINERY

Simplify your workflow.

MABI is a leading supplier of sheet metal working machines for insulation technology.

Find out how you can optimise your processes with MABI insulation machines.

Contact us - we would be happy to attend to your queries.

Your MABI team.

Smart Factory

Step 1: Measurement

MABI Evo-Net

MABI Evo-Net includes a range of software. You will control: From Job-site till production. Everything out of one hand. MABI develops continuously this Software by themselves. This ensures a smooth running Prefab production.

Step 2: 3D scanning

MABI Evo-Net-Scan

A high-speed 3D laser scanning system for referencing, linking and refining scanned and BIM data directly at the construction site. We recommend using one of the most successful 3D scanning systems available on the market: the Trimble X7.

Fully register and compare the individual scans at the construction site and record images, comments and local coordinates. The result is a point cloud containing all details and information that can still be checked on site and is ready to export in standard file formats. Your benefit: You can also access and read the data later on in the office.

Absolute reliability for all scanning processes thanks to the first smart automatic calibration system in the sector. It ensures you can work productively without any enforced breaks and expensive service times.

Further information is available here.

What is BIM?

Building Information Modeling (BIM) is used for the development and operation of buildings using digital data that can be accessed by all of the people involved in the construction process.

Step 3: Interface

Open interface. Customized for your company.

Do you have existing data and don’t know what to do with it?

We know what you want and that's why we offer you an individual user interface to feed Evo-Net with your data.

ISOCOM from Com Cad

The interface to ISOCOM provides many more advantages, from simple measurement & calculation to invoicing.

Suitable for the following machines:

- MABI Laser 2

- MABI Bingo 4E EVO

- MABI Bingo 16-Z EVO

- MABI Bingo 2 EVO

Further information can be found here.

Step 4: Monitoring

Access the data in real time

As a sheet metal processing company faced with a growing number of product variants and shorter order times, you need a strategy to remain viable in the future. Standing still is not an option. The industry 4.0 interface comprises a collection of data that can be accessed in real time and then processed externally.

This data includes e.g. the following information:

- Which order is currently being processed

- When was the start signal sent to the controller

- When was a new processing stage activated (e.g. processing stage #2 was started 45 seconds after the program was launched)

- Info on the number of parts, number of holes and number of geometrical elements are supplied for each processing stage

- When was the program paused or even cancelled by the user

- When was the program cancelled due to an error on the controller

- When was the program successfully completed

Step 5: Labelling

Add structure to your work processes

Use QR codes/barcodes on labels for clear labelling and identification. Essential for rational further processing.

Add structure to your work processes from the collection of the data right through to billing:

- Freely configure your own item numbers based on your specifications with the Evo-Net Item Generator.

- Export the data based on the item number to Excel or your ERP system.

ISOCOM (Com Cad)

ISOCOM from Com Cad

Alternatively, it is possible to carry out the measurement by ISOCOM:

- Duct measurement

- Piece/tube allowance

- Cap allowance

- Handover in project/offer

- Output according to GAEB DA 11

- Various printouts

The interface to ISOCOM provides many more advantages, from simple measurement & calculation to invoicing.

Suitable for the following machines:

- MABI Laser 2

- MABI Bingo 4E EVO

- MABI Bingo 16-Z EVO

- MABI Bingo 2 EVO

Further information can be found here.

BIM (Building Information Modelling)

Today, BIM is mainly discussed under planning and approval aspects. Working with digital building information models offers new possibilities that result from the continued use of existing project data (regardless of the project status).

By consistently using the BIM method, as is standard in other industries, we expect an increase in productivity in value creation for construction and operation that goes beyond planning and approval. Jobs in construction will become more attractive due to the increase in digitalization and the more intensive use of BIM, and can help compensate for the shortage of skilled workers shortage.

MABI is in close contact with research institutes and universities in order to remain at the forefront of BIM in the future.

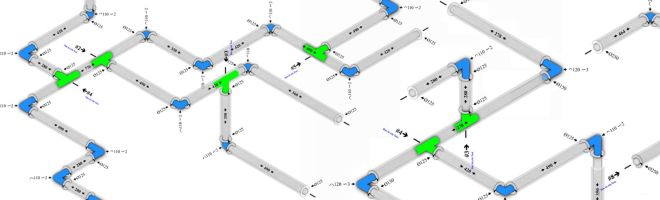

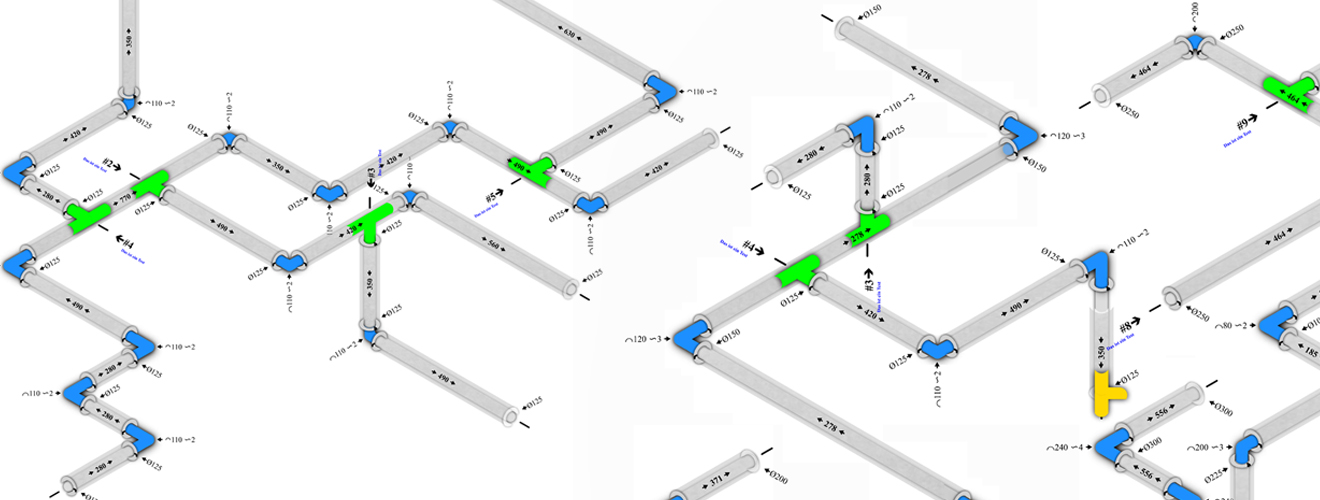

MABI IsoPlaner

From the site measuring sheet to production. Simple, clear, without detours.

Practically nothing changes for the surveyor. During development, the familiar environment of the surveyor was consistently taken into account. Clear symbols such as the marking of the seam position are clear indications of the simple operation and the typical MABI user-friendliness.

Learn about the success stories of our customers.

MABI machines are used worldwide and are among the most successful on the market.

”The only thing I regret is that I did not decide to invest in a MABI a few years earlier."

(often heard statement from our customers)

Events

Experience live how MABI insulating machines can optimise your processes.

Career and education

Are you looking for a future at the highest level of quality and with a high degree of personal responsibility? And this in a professional environment?

Welcome to MABI.

MABI Insulation machinery

Rational and efficient sheet metal processing since 1969. It is mainly due to our employees that the years following this beginning have been so successful. Their knowledge and ability have enabled us to leverage the experience gained in the pioneering days to become a successful company. Without doubt, MABI is a team effort in which each individual employee counts. Without these employees, MABI would not be what it is today. And I am particularly proud of the fact that most of them have stayed with us. Needless to say, our customers have also influenced and shaped our company. In 1982, when the first 3000M (mechanical) machine was unveiled, we could not be at all sure whether it would be able to hold its own on the market.

In 1984 the first ‘pilot’ customers started to buy the MABI 3000E (electronic). This was definitely a technological and economic risk but also a leap of faith in a novel cutting machine for the production of segmental pipes. The trust invested by these first buyers formed the basis for our success and everything that followed. This is why I would like to express my thanks to all those customers who placed their trust in us from the beginning. Without them we would not exist. And I am particularly pleased that they still count among our customers. I would also like to thank those customers who came to us over the ensuing years. When we look back on the technological development over the course of all those years, we received new impetus from many companies around the world. For a machine and systems manufacturer like us, customers and their desires and expectations are the most important drivers for innovation and creativity. Today our customers can choose from a wide range of equipment, from low-cost beading machines to fully automated manufacturing centres, which all come with MABI’s usual first-class service. As a ‘one-stop shop’, MABI also programmes and develops its own software.

With this letter, I would like to thank you for your suggestions and our intensive, open, and trustful dialogue. Please keep your inputs coming and keep challenging us.

Max Biland

(Founder of MABI AG)

MABI is a member of: EIIF (European Industrial Insulation Foundation)

Industrial companies across all sectors and geographical locations are faced with the challenge of reducing costs while reducing their environmental footprint. EiiF has been set up to promote and establish the use of industrial insulation as a widely understood and accepted means of meeting these interrelated requirements.

MABI is a member of: NIA (National Insulation Association®)

The National Insulation Association® (NIA) is a not-for-profit trade association representing merit (open shop) and union contractors, distributors, laminators, fabricators, and manufacturers that provide thermal insulation, insulation accessories, and components to the commercial, mechanical, and industrial markets throughout the nation. Since 1953, the northern Virginia–based association has been the voice of the insulation industry and is dedicated to keeping the commercial and industrial insulation industry up-to-date on the latest industry trends and technologies.

The online workshop planning

Unnecessary idling costs time and money. A MABI workshop plan can optimise your production process. This is a free service from MABI - call us and we will gladly advise you on workshop optimization. Or try it yourself.

Open planner