Smart Factory

Data-based services for your production.

Benefit from data-based services as an opportunity to have successful and cost-effective production - also in the future. With Smart Factory, you always have the information relevant to your machine at the right time.

Join us on the way to a smart future!

Step 1: Measurement

MABI Evo-Net

MABI Evo-Net includes a range of software. You will control: From Job-site till production. Everything out of one hand. MABI develops continuously this Software by themselves. This ensures a smooth running Prefab production.

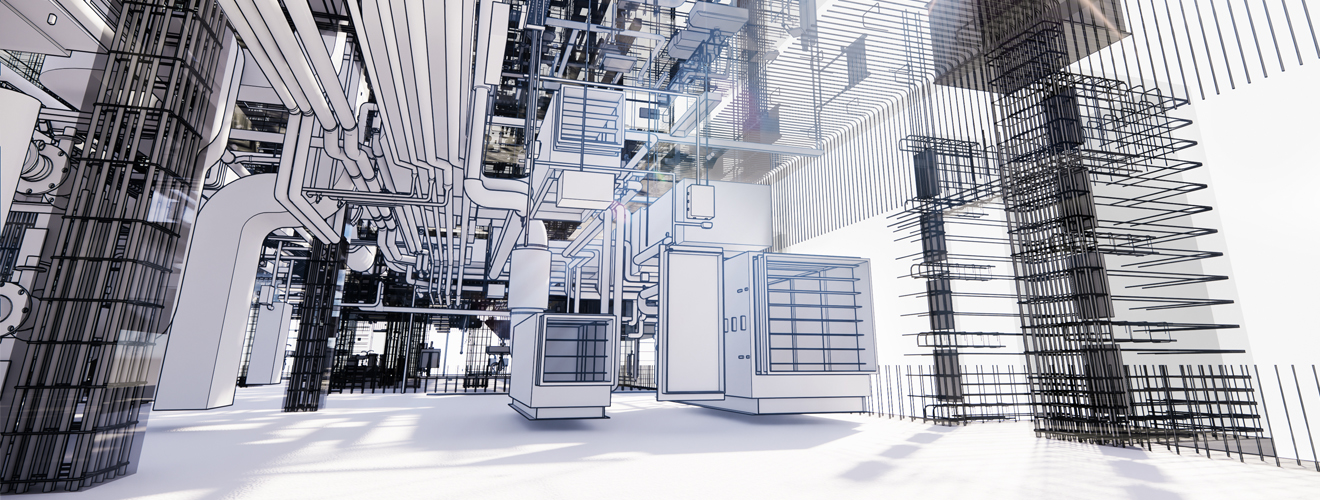

Step 2: 3D scanning

MABI Evo-Net-Scan

A high-speed 3D laser scanning system for referencing, linking and refining scanned and BIM data directly at the construction site. We recommend using one of the most successful 3D scanning systems available on the market: the Trimble X7.

Fully register and compare the individual scans at the construction site and record images, comments and local coordinates. The result is a point cloud containing all details and information that can still be checked on site and is ready to export in standard file formats. Your benefit: You can also access and read the data later on in the office.

Absolute reliability for all scanning processes thanks to the first smart automatic calibration system in the sector. It ensures you can work productively without any enforced breaks and expensive service times.

Further information is available here.

What is BIM?

Building Information Modeling (BIM) is used for the development and operation of buildings using digital data that can be accessed by all of the people involved in the construction process.

Step 3: Interface

Open interface. Customized for your company.

Do you have existing data and don’t know what to do with it?

We know what you want and that's why we offer you an individual user interface to feed Evo-Net with your data.

ISOCOM from Com Cad

The interface to ISOCOM provides many more advantages, from simple measurement & calculation to invoicing.

Suitable for the following machines:

- MABI Laser 2

- MABI Bingo 4E EVO

- MABI Bingo 16-Z EVO

- MABI Bingo 2 EVO

Further information can be found here.

Step 4: Monitoring

Access the data in real time

As a sheet metal processing company faced with a growing number of product variants and shorter order times, you need a strategy to remain viable in the future. Standing still is not an option. The industry 4.0 interface comprises a collection of data that can be accessed in real time and then processed externally.

This data includes e.g. the following information:

- Which order is currently being processed

- When was the start signal sent to the controller

- When was a new processing stage activated (e.g. processing stage #2 was started 45 seconds after the program was launched)

- Info on the number of parts, number of holes and number of geometrical elements are supplied for each processing stage

- When was the program paused or even cancelled by the user

- When was the program cancelled due to an error on the controller

- When was the program successfully completed

Step 5: Labelling

Add structure to your work processes

Use QR codes/barcodes on labels for clear labelling and identification. Essential for rational further processing.

Add structure to your work processes from the collection of the data right through to billing:

- Freely configure your own item numbers based on your specifications with the Evo-Net Item Generator.

- Export the data based on the item number to Excel or your ERP system.

ISOCOM (Com Cad)

ISOCOM from Com Cad

Alternatively, it is possible to carry out the measurement by ISOCOM:

- Duct measurement

- Piece/tube allowance

- Cap allowance

- Handover in project/offer

- Output according to GAEB DA 11

- Various printouts

The interface to ISOCOM provides many more advantages, from simple measurement & calculation to invoicing.

Suitable for the following machines:

- MABI Laser 2

- MABI Bingo 4E EVO

- MABI Bingo 16-Z EVO

- MABI Bingo 2 EVO

Further information can be found here.

BIM (Building Information Modelling)

Today, BIM is mainly discussed under planning and approval aspects. Working with digital building information models offers new possibilities that result from the continued use of existing project data (regardless of the project status).

By consistently using the BIM method, as is standard in other industries, we expect an increase in productivity in value creation for construction and operation that goes beyond planning and approval. Jobs in construction will become more attractive due to the increase in digitalization and the more intensive use of BIM, and can help compensate for the shortage of skilled workers shortage.

MABI is in close contact with research institutes and universities in order to remain at the forefront of BIM in the future.

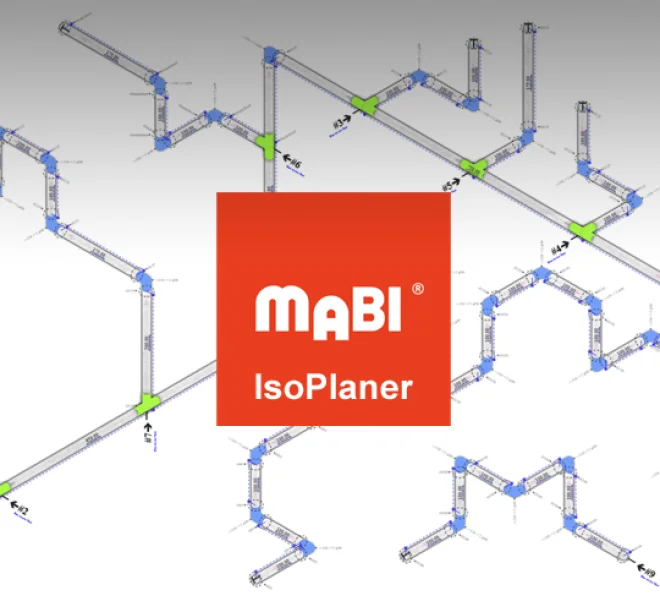

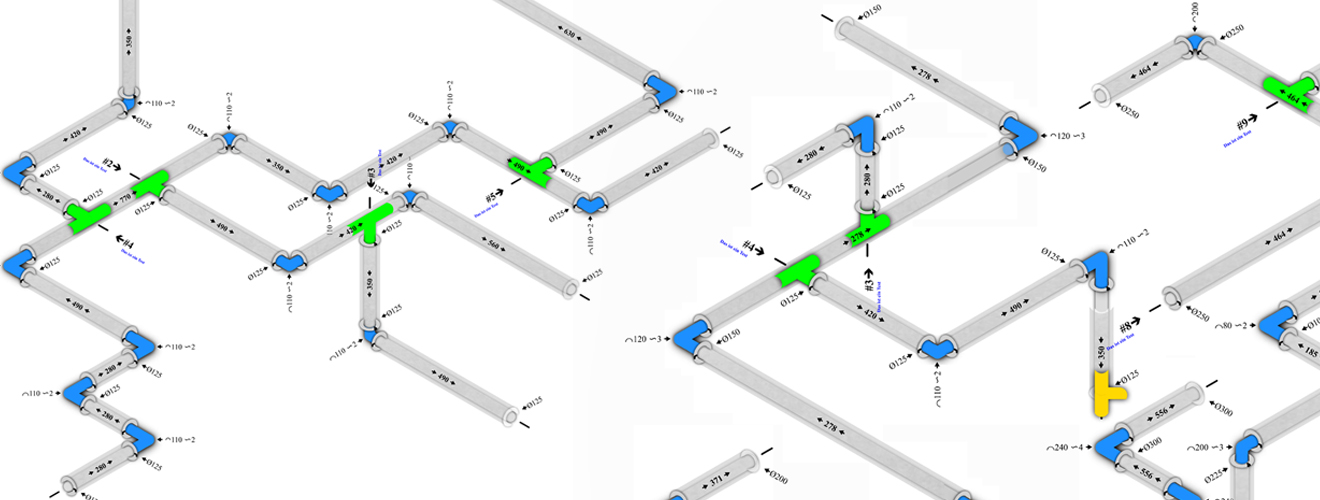

MABI IsoPlaner

From the site measuring sheet to production. Simple, clear, without detours.

Practically nothing changes for the surveyor. During development, the familiar environment of the surveyor was consistently taken into account. Clear symbols such as the marking of the seam position are clear indications of the simple operation and the typical MABI user-friendliness.